ZENITH MECHANICS

Our Products

We also market Oxygen and Nitrogen generators of Summits Hygronics brand.

Screw Compressor

. Zenith Mechanics permanent magnet VSD Screw Air Compressor is trending in the industry because of its energy saving and high efficiency! It can directly bring the electricity cost down by 20% to 40%. The compressor delivers only the required air flow and consumes required only. When air consumption is low, the air compressor will automatically run at lowest speed and save much energy.

This is 10 HP

This is 15 HP

Screw Compressor

Water Cooled Compressor

High Pressure Reciprocating Air Compressor

Zenith Mechanics permanent magnet VSD Screw Air Compressor is trending in the industry because of its energy saving and high efficiency! it can directly bring the electricity cost down by 20% to 40%. The compressor delivers only the required air flow and consumes required only. When air consumption is low, the air compressor will automatically run at lowest speed and save much energy.

Air Cooled Compressor

High Pressure Reciprocating Air Compressor

Zenith Mechanics permanent magnet VSD Screw Air Compressor is trending in the industry because of its energy saving and high efficiency! it can directly bring the electricity cost down by 20% to 40%. The compressor delivers only the required air flow and consumes required only. When air consumption is low, the air compressor will automatically run at lowest speed and save much energy.

Screw Air Compressor

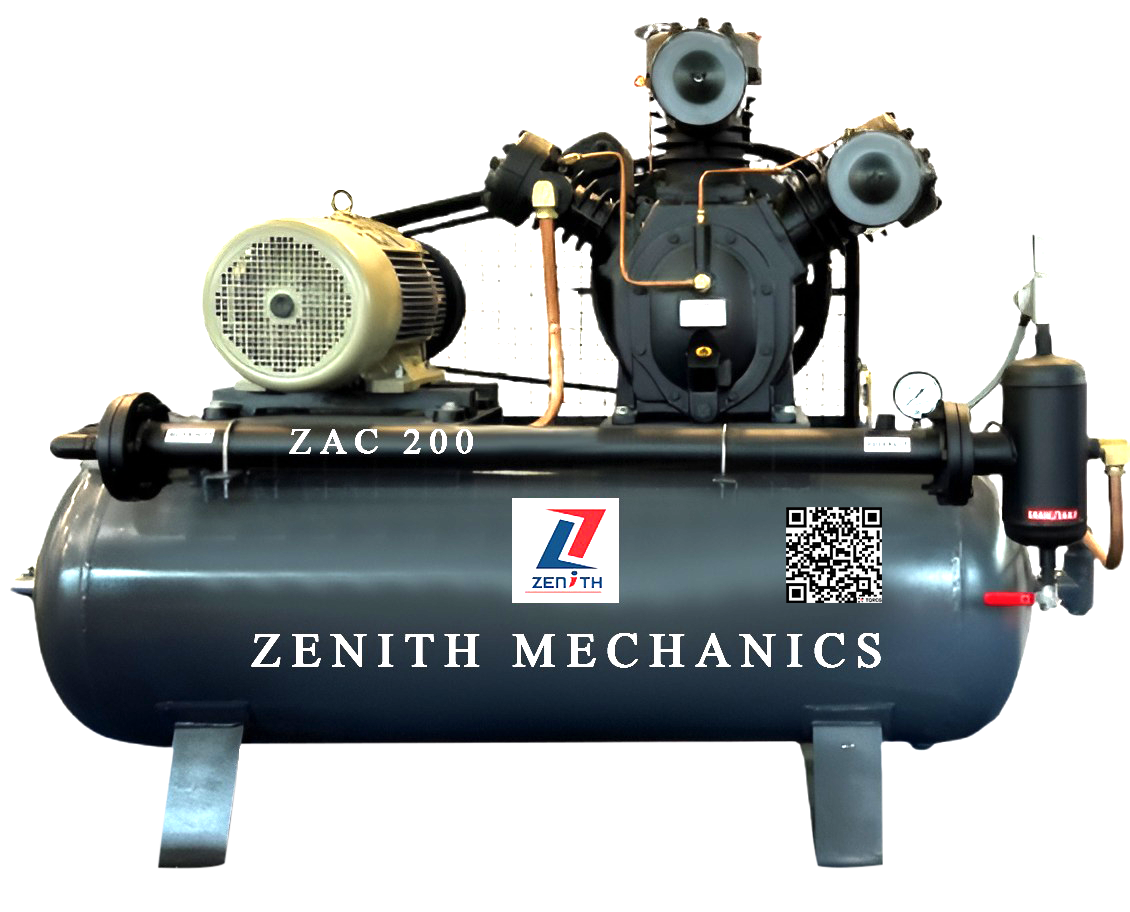

High Pressure Reciprocating Air Compressor

Zenith Mechanics permanent magnet VSD Screw Air Compressor is trending in the industry because of its energy saving and high efficiency! It can directly bring the electricity cost down by 20% to 40%. The compressor delivers only the required air flow and consumes required only. When air consumption is low, the air compressor will automatically run at lowest speed and save much energy.

Two Stage Reciprocating Air Compressor

High Pressure Reciprocating Air Compressor

Zenith Mechanics permanent magnet VSD Screw Air Compressor is trending in the industry because of its energy saving and high efficiency! it can directly bring the electricity cost down by 20% to 40%. The compressor delivers only the required air flow and consumes required only. When air consumption is low, the air compressor will automatically run at lowest speed and save much energy.

Dry Air Generator

Why Dry Air Generator

Dry Air Generator is a Combo Pack with Air Compressor, Compressed Air Filters, Refrigerated Type Air Dryer and Desiccant Type Air Dryer designed for absorbing moisture from compressed air. This system will achieve ISO 8573: high quality of class – 1 air. This is an essential device used in various industrial applications specially for transformer testing purposes. It is mostly used in the electrical power industry.

Heatless Air Dryer

It provides compressed air as per ISO 8573 standards at most economical costs.

Key Features

- Removes moisture with PSA system.

- Activated Alumina or Molecular Sieves are used as desiccant.

- Optimized energy costs and performance.

- Adjusts automatically to varying inlet and ambient conditions.

- Uses twin desiccant towers and strategically positioned valves for best output.

- Triple filtering system to meet stringent air quality standards.

- Reliable and time-proven technology, used in industries worldwide.

Air Receiver

There are two different types of air receivers in a compressed air system – the PRIMARY receiver (located near the compressor, after the after-cooler but before filtration and drying equipment) and the SECONDARY receiver (located close to points of larger intermittent air consumption).

Key Features

- Reliable compact design, simple installation & lifetime flexibility.

- Fabricated as per ASME SEC VIII Dis I/IS:2825 with hydrostatic test.

- Anti-corrosive paint on the inside & double coating of zinc chromate paint on the outside.

- Helps in pressure stabilization and modulates the sequence of the compressor.

- Improves the longivity and reliability of the compressor.

- Performs a preliminary separation and removal of condensate.

- Zenith Air Receivers come equipped with standard accessories.

Automatic Drain Valves

Automatic Drain Valves sense the condensate level for activation, and remove mixtures of water and compressor lubricants from compressed air systems, therby ensuring no loss of compressed air without shutting down the system.

Key Features

- Compact, Sturdy design.

- Variable on time and cycle time.

- Large, cleanable orifice for heavy condensate discharge.

- Screw threads structure at inlet and outlet for easy installation & servicing.

- Air flow indication marked on valve body.

- Zero Air Loss while removing condensate.

- Helps save energy and increase the lifespan of the system.

Compressed Air Filters

Purification of compressed air is essential as in the compressed state these contaminants become concentrated and cause damage to the system.

Key Features

- High grade aluminium-alloy and carbon-steel housing surface, painted with epoxy resin for wear & corrosion resistance.

- Screw threads structure at inlet and outlet for easy installation with air flow indication on the housing.

- Level indicaror to monitor critical level for downstream pollution prevention.

- Outlet air quality confirm ISO8513.1 quality class.

- Reliable automatic drain.

- Protects the pipe from corrosion & increases lifetime of tools and equipments.

- Update pressure indicator to secure element replacement.

Oxygen Generators

Summits Hygronics is also a certified ISO 13485 firm (Medical Device Quality Management).

Key Features

- Automatic, Uninterrupted Oxygen generation on demand.

- Online purity indication with highest purity up to 96%.

- Audio-visual alarms and Analog output for remote monitoring Mimic display for PSA functions

- Activated carbon tower and coalescing filters remove oil up to 0.01mg/m3

- Specially Coated Medical Grade Internals

- Economical, low maintenance system – eliminates production downtime

- Safe and convenient over high-pressure cylinders

Nitrogen Generators

The major components of PSA Nitrogen Generator are a pair of Adsorbers, surge tanks, switching valves, intelligent PLC with touch screen display, Gas analyzer and other instruments.

Key Features

- Intelligent PLC with online purity indication

- User friendly 4.3 to 7 inch TFT Touch screen

- Animated real time process display

- Auto cut-in & cut-off based on demand

- RS 485 MODBUS interface for remote monitoring

- Inbuilt Data logger stores minimum 50 alarms/trips

- Announcement for filter cartridge replacement