ZenithSince 2012

Air Purification Systems are designed to improve indoor air quality by removing pollutants, allergens, and harmful substances from the air. These systems use various technologies such as HEPA filters, activated carbon filters, UV-C light, ionizers, and other methods to purify the air in residential, commercial, and industrial environments.

14+ Years of Experience in Consultaking Manufacturer

MORE ABOUT US

We Provide Best Business

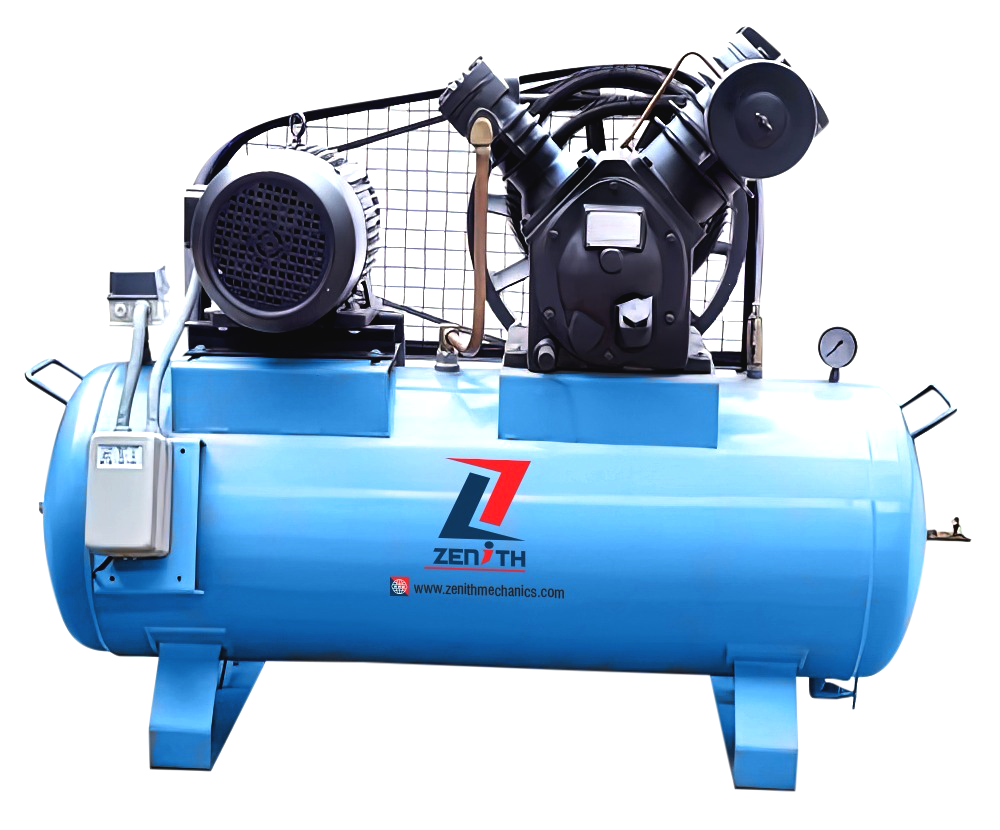

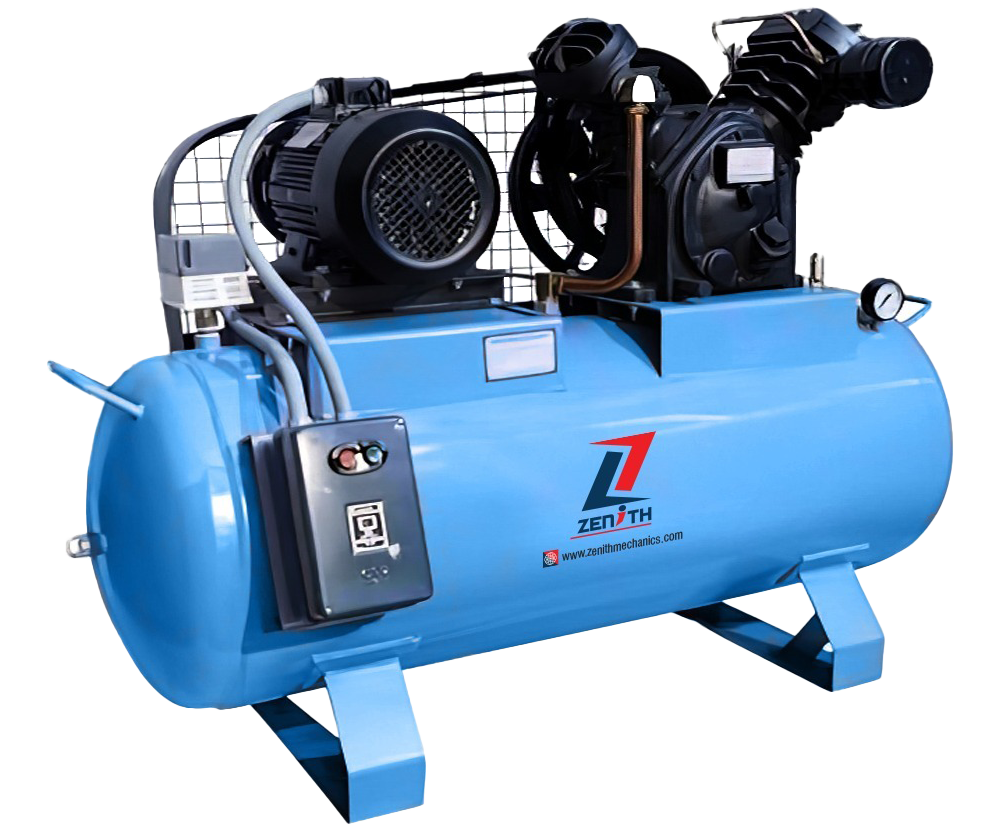

Zenith Mechanics is one of the most well known manufacturers of Air Purification Systems and accessories in Eastern India. Our products are renowned for their supreme quality standards and extreme durability.

Led by proprietor, Mr. Pradip Ray, with an experience of more than 3 decades in this field, Zenith Mechanics has flourished as the only large successful manufacturer of Air Dryers in the Eastern Region of India.

- Teamwork

- Relationships

- Sincerity

- Good people

- Quality Maintain

- Honesty

- Rewarding

- 24 Hours Services

- Accountability

- Delivery Commitment

We Started Our New product

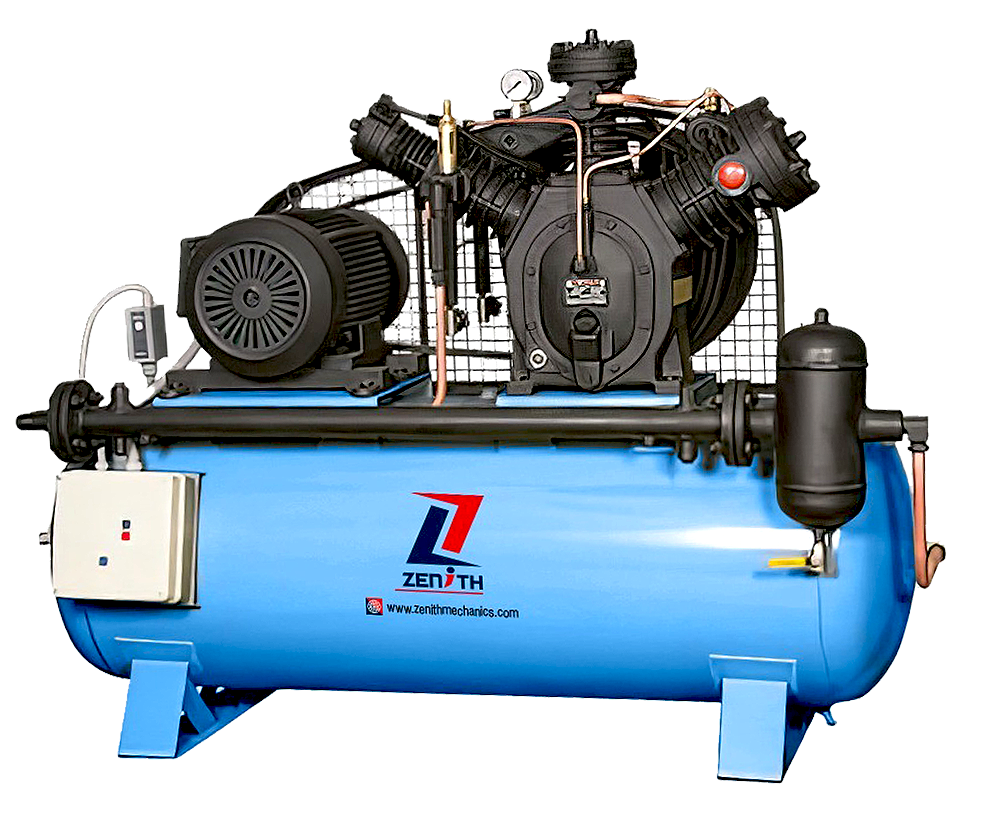

Air Compressor

AIR COMPRESSOR AND AIR PURIFICATION SYSTEM

COMPRESSOR &

AIR DRYER MANUFACTURER W.B.

PRODUCT FEATURE

Refrigerated Air Dryer

Why Compressed Air Dryer

Refrigerated Compressed Air Dryers are one of the most common used types of Air Dryers. It is simple in design, requires very little maintenance and cost effective. Generally where the buyers don’t have special requirements, like an ultra-low dew point – The refrigerated Air Dryer is the suitable option to protect the tools and equipments.

Heatless Air Dryers

Why Heatless Air Dryers

The Compressed air leaving a compressor contains considerable quantities of water vapor. If the untreated air is supplied into the distribution lines, the moisture would condense to liquid water as it gets cooled. Condensed water is a major cause of downtime in compressed air systems. Water causes rust, pitting, blockages and freeze ups, which results in component failure and product rejection. The only way to prevent condensation of water in air lines is to lower the dew point of the air in the system. It is less expensive to own and operate an air dryer than to live with the problems it can prevent.

Air Receiver

Why Air Receiver

Air Receiver is essential to every compressed air system to act as a buffer and a storage medium between the compressor and the consumption system. There are in principal two different air receivers in a compressed air system :

PRIMARY receiver – located near the compressor , after the after-cooler but before filtration and drying equipment

SECONDARY receivers – located close to points of larger intermittent air consumption

Automatic Drain Valve

Why Automatic Drain Valve

Condensate can have harmful effects on a system when not removed. Moisture can wash lubrication from air tools and production equipment causing downtime, production quality problems and maintenance. Excessive rust and scale can form in the air distribution system.

The task of the condensate drain valves is to remove condensate from the air system without losing excessive compressed air and without shutting down the system.

Compressed Air Filter

Why Compressed Air Filter

The result is damage to the system and more particles generated. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides, and dirt. By applying proper filtration system the above can be eliminated.

Dry Air Generator

Why Dry Air Generator

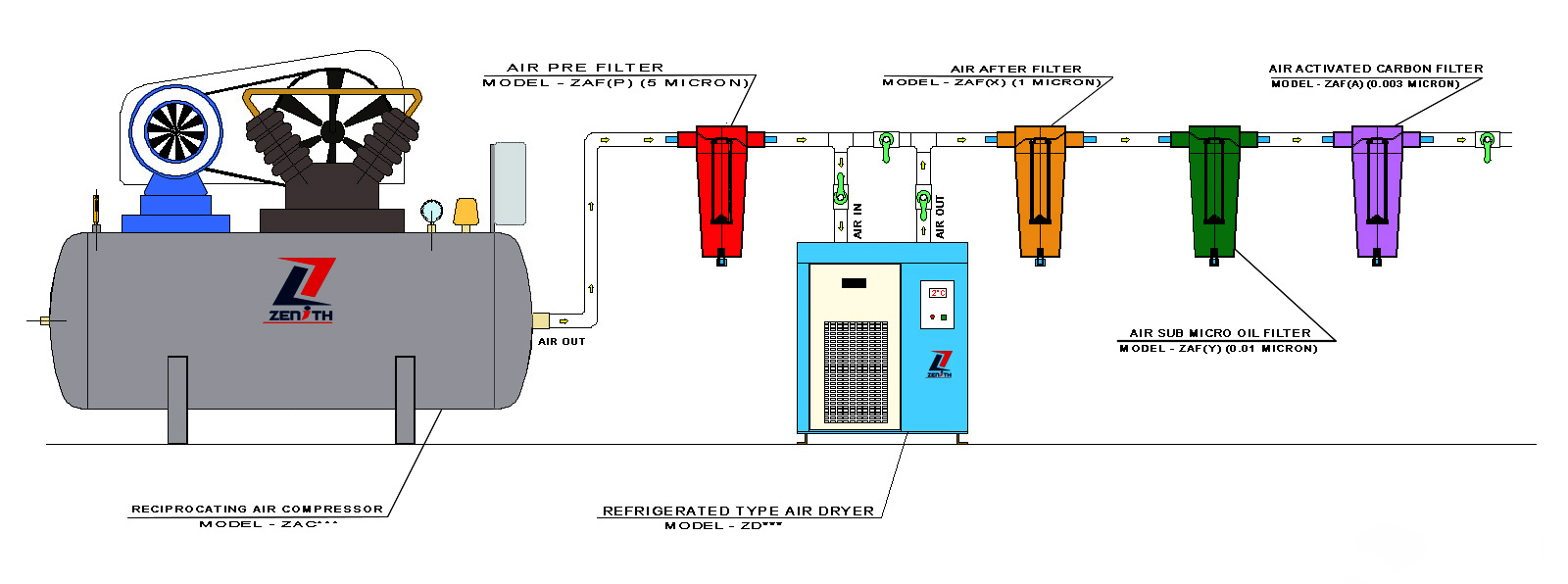

Dry Air Generator is a Combo Pack with Air Compressor, Compressed Air Filters, Refrigerated Type Air Dryer and Desiccant Type Air Dryer designed for absorbing moisture from compressed air. This system will achieve ISO 8573: high quality of class – 1 air. This is an essential device used in various industrial applications specially for transformer testing purposes. It is mostly used in the electrical power industry.

Our Participation Trophy

OUR CLIENTS